Principe

The device is placed horizontally handle on the top, in the middle of the autoclave chamber like a regular Bowie & Dick test pack.

When the sterilisation cycle is finished, data is transmitted remotely via a wireless connection and through the autoclave walls, to the WI SCAN® System Reader.

The operating agent can view the reader screen to ensure the smooth running of the cycle.

The Reader keeps data as long as it is transferred to the computer via an USB cable.

Then, Bowie & Dick cycle data is analyzed and stored on computer.

Additional information required for registration and traceability is entered on the WI SCAN software by the operating agent.

How does it work ?

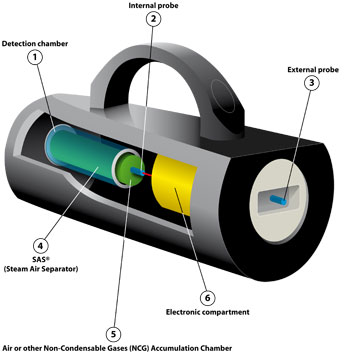

The WI SCAN® Electronic Bowie & Dick Test is made of a cylindrical detection (1) chamber closed at one end and two temperature probes. The internal temperature probe (2) is located in the rear part of the detection chamber and the external probe (3) on the surface.

During the sterilisation cycle, after air extraction, the mixture of steam and NCG (Non-Condensable Gases) progresses along the chamber where steam condensates and the proportion of air or NCG increases reaching the maximum level at the rear of the chamber.

The combination of several innovative features allows the Electronic Bowie & Dick Test to reach high standards in detection, precision and result REPRODUCTIBILITY:

Horizontality of the detection chamber:

At the same temperature, the density of air or other NCGs is superior to the density of the saturated steam. The horizontal detection chamber facilitates steam penetration and its detection. The feature allows the controlling of the steam penetration in all autoclave types and all types of sterilisation cycles (as defined by: ISO 11140-4):

-

Sub- atmospheric cycle pulses

-

Trans -atmospheric cycle pulses

-

Super- atmospheric cycle pulses.

Air or other NCG separation from Steam through the SAS® (Steam Air Separator):

In the detection chamber, the SAS® device (patent pending) , acts as a porous load enabling steam condensation. This liquid condensation is then eliminated by gravity outside the device, allowing air or other NCG, to penetrate to the rear of the detection chamber. The presence of air or NCG is therefore amplified allowing more accurate detection.

Air or other NCG stabilisation:

In the accumulation chamber, the SAS® also prevents recombination of air or NCG with steam until the end of the sterilisation plateau at 134°C .

Furthermore, thanks to the SAS®, the temperature measurements are more accurate and allow the most precise results ever obtained from Bowie & Dick tests to be got.

Air extraction and steam penetration algorithm:

In the electronic compartment (6) an algorithm developed by STERLAB, measures the temperature difference between the two probes (external and internal) during various stages of the Bowie & Dick sterilisation cycle. This algorithm gives the “Pass/Fail” result and indicates the “security margin”.

Operating instructions

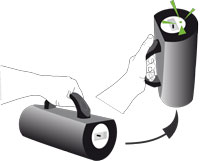

1To switch on, place the device vertically with the white side on the top for a few seconds. |

|

|

2Place the Electronic Bowie & Dick Test horizontally, handle on the top, in the middle of the autoclave chamber like a regular Bowie & Dick test pack. |

|

|

3When the sterilisation cycle is over and the autoclave opened the flashing LED indicates automatically the results. |

|

|

4Accelerated flashing LED indicates that the wireless data transmission to the WI SCAN® Reader is possible. |

|

|

5Transferred data is archived on a computer via the USB cable connection. |

|

|

Significant innovative features

Autoclave diagnostic tool: security margin

In a case of a PASS Result and through the "Administrator mode" you can visualise the SECURITY MARGIN data.

The outstanding precision of measurement through the SAS® allows the definition of the security margin of the autoclave:

-

if no air or NCG are detected, the security margin is set at 100%.

-

if the quantity of air or NCG reaches the ISO 11140-4 failure criteria, the security DOES NOT EXIST.

Each PASS Result will be therefore accompanied by its Security Margin, set between 5% and 100%, allowing an early autoclave malfunction detection (early warning) or confirming the adequate autoclave performance.

Continuous re-use

The WI SCAN® Electronic Bowie & Dick Test gives reproductive results for 400 cycles.

When approaching the calibration limit of 400 cycles of use, an early warning indicates on the table of results the number of remaining cycles.

The Manufacturer-Sterlab, provides annual probe recalibration and battery renewal allowing the device to be reused continuously year after year.

This non-disposable policy induces the reduction of various costs (procurement cost, storage, shipping, recycling cost ) in line with Sterlab’s environmental friendly policy.

Technical data

- Accuracy: ± 0.2° C at 134° C

- Scanning rate: 2 seconds

- Data Memory: 1hour of data acquisition

- Autonomy: 400 cycles

- Recalibration frequency: 400 cycles

- The WI SCAN® Electronic Bowie & Dick Test is tested according to methods described in ISO 11140-4 and ISO 11140-5

- Weight : 2.4 kg

- Complies with sub-atmospheric, trans-atmospheric and super-atmospheric cycle pulses

- Requires the WI SCAN® Reader WISCAN01 and the WI SCAN® software WISOFT01

- Cooling time between two uses: 3 hours minimum

- Automatic switch-on by vertical rotation of the device

- Instant switch-off after data transfer to the WI SCAN® Reader

- Do not use with other cycles than standard Bowie & Dick tests (134° C - 3.5 min)

- Data transfer to the WI SCAN® Reader via RF 2,4 Ghz

- WI SCAN® software compatible with PC Windows XP or later

- "Help" function included in the software

- Storage conditions: between 15°C- 35°C, horizontally , handle on the top.

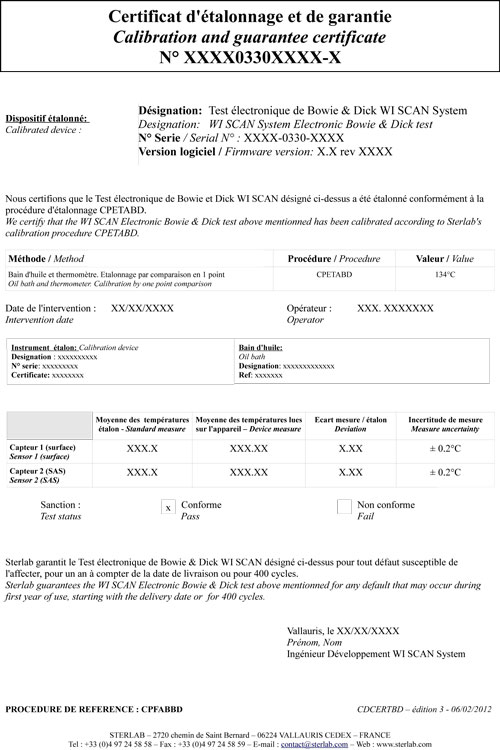

Certificates

A milestone in the electronic sterilisation control...!

After the electronic sterilisation controllers, Sterlab breaks new ground again by imagining a new electronic Bowie & Dick test.

The Sterlab Research and Development team has patented a new air and NCG detection concept to analyse autoclave steam, which brings a never yet obtained reliability in Bowie & Dick tests for all pre-vacuum autoclaves.

The WI SCAN® electronic Bowie & Dick test will simplify controls, suppress the use of paper, optimise costs with the reader/software architecture of the existing WI SCAN® System to read and save electronic data.