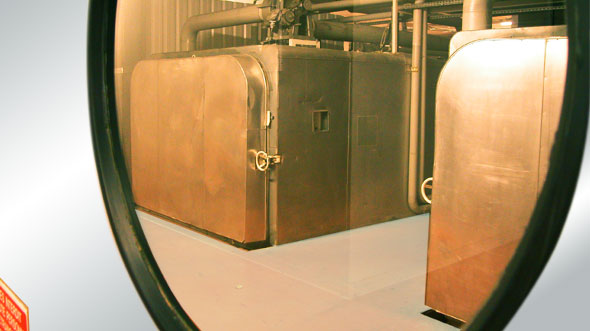

Infrastructure

Under one roof of 1500 mm2 we offer:

-

1 sterilisation chamber of 60 m3

-

2 chambers of 40 m3

-

1 chamber of 36 m3

-

1 chamber of 2 m3

-

1 hot and ventilated room of 320 m3 dedicated to accelerated desorption with references in accordance with 21 CFR Part 11.

Sterlab offers a complete E.T.O. service: several sterilisation cycles to meet your needs and constraints

We can vary the parameters of your cycles:

-

Ethylene Oxide concentration

-

Temperature

-

Relative humidity rate

-

Duration of the gas exposure

-

gaz

-

Pressure.

Sterlab ®sterilization cycles are characterized by the completion of pre-treatment, gas exposure and gas desorption in the same chamber

The integrity and homogeneity of the sterilised batches are guaranteed throughout the sterilisation process and up to the storage area.

Sterlab as the inventor have been implanting this All -In-One process for over 20 years.

The dynamic desorption is achieved by a series of vacuums and air injections in the chamber to remove in a minimum time the residual ethylene oxide.

Sterilised products are available for collection 48hours after being released from the chamber.

Documentation .pdf

An adequate infrastructure located at Sophia-Antipolis and effective equipment coupled with over 20 years of experience in ethylene oxide sterilisation

Our services cover the following areas:

-

Ethylene oxide sterilisation

-

Ethylene oxide decontamination

-

Validation of sterilization according to ISO 11135-1.

|

|

|

|

|

|

|

|

|

|

|

|